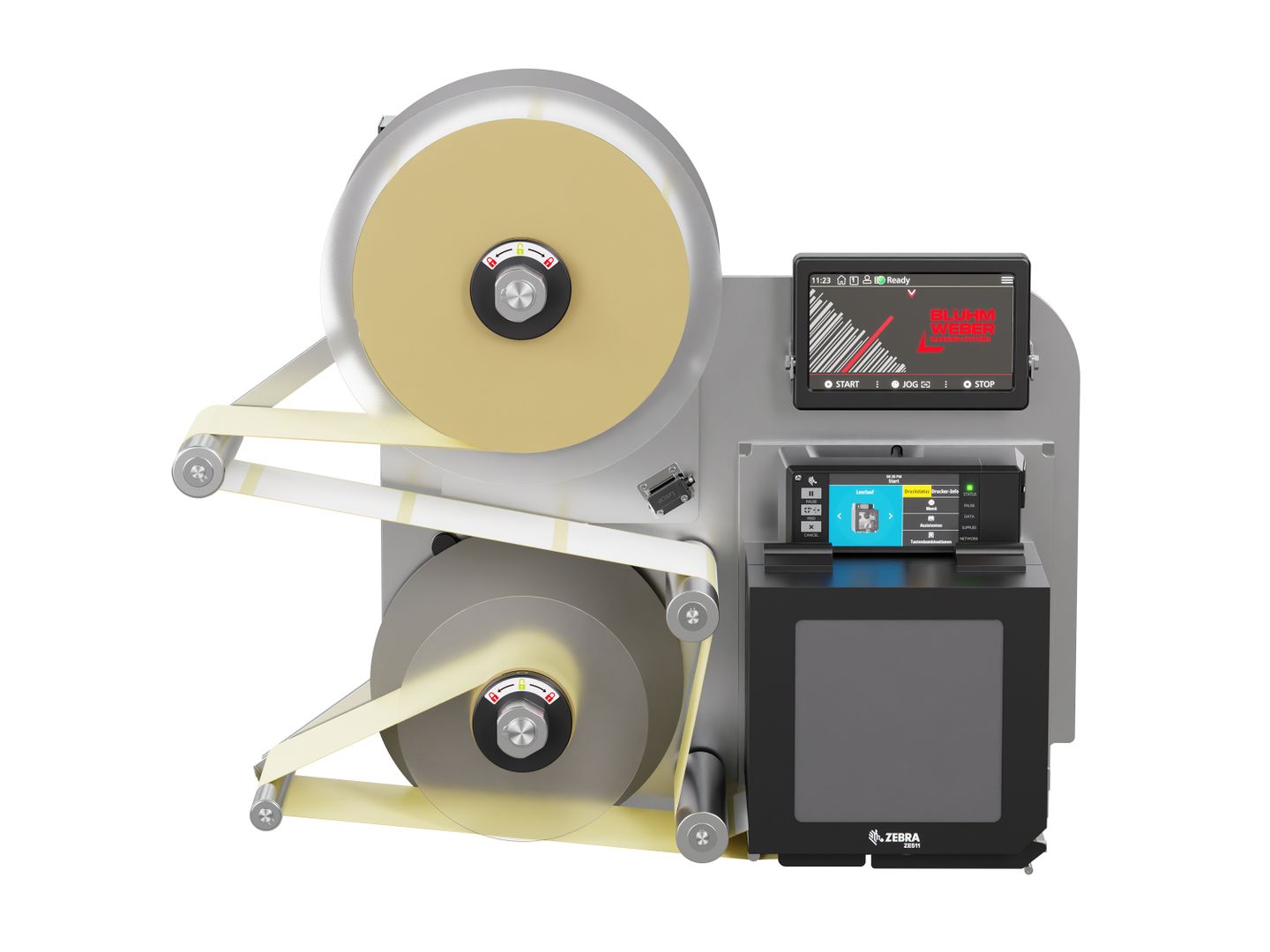

1,500 applicator variants for all positions and formats

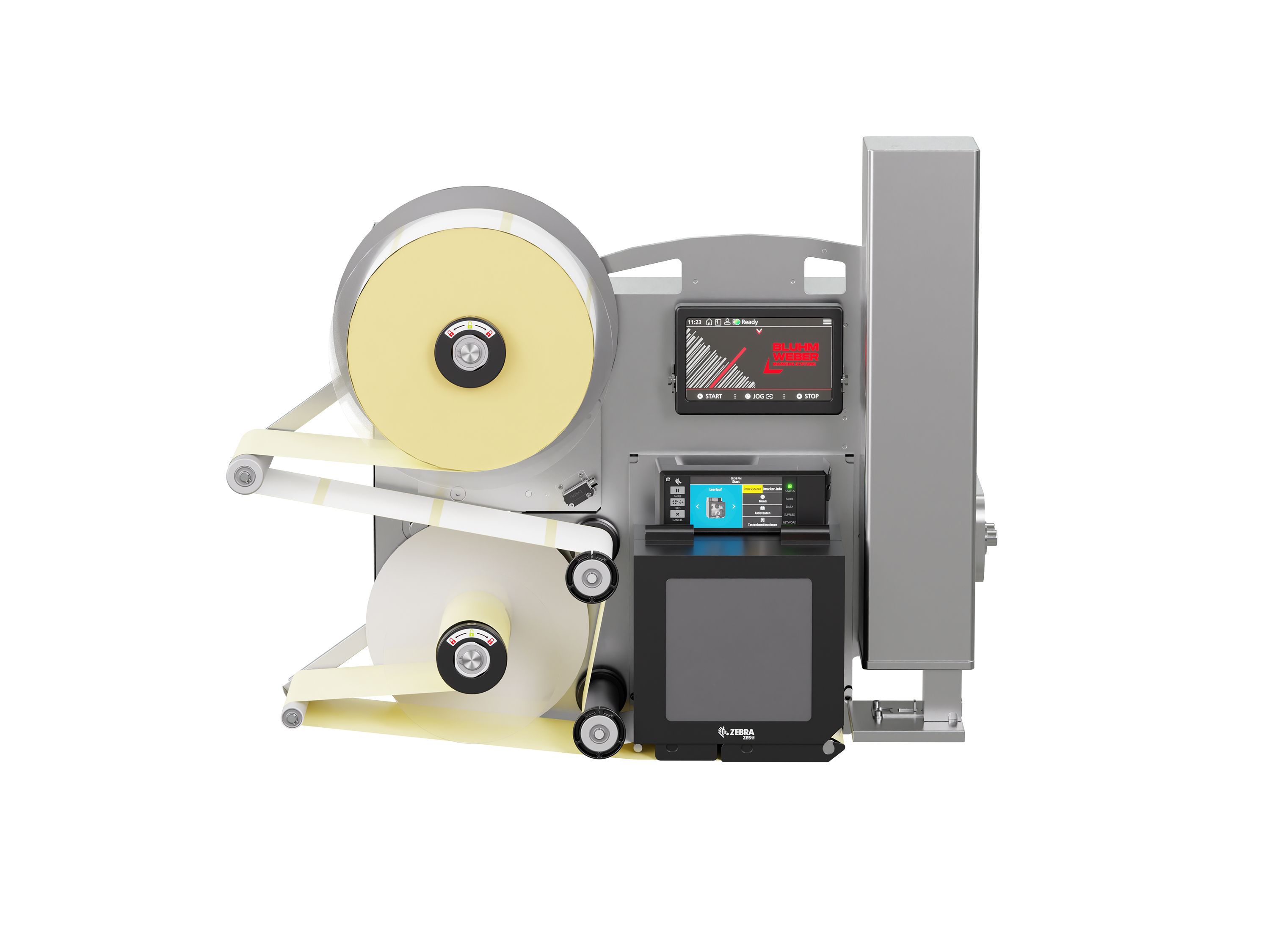

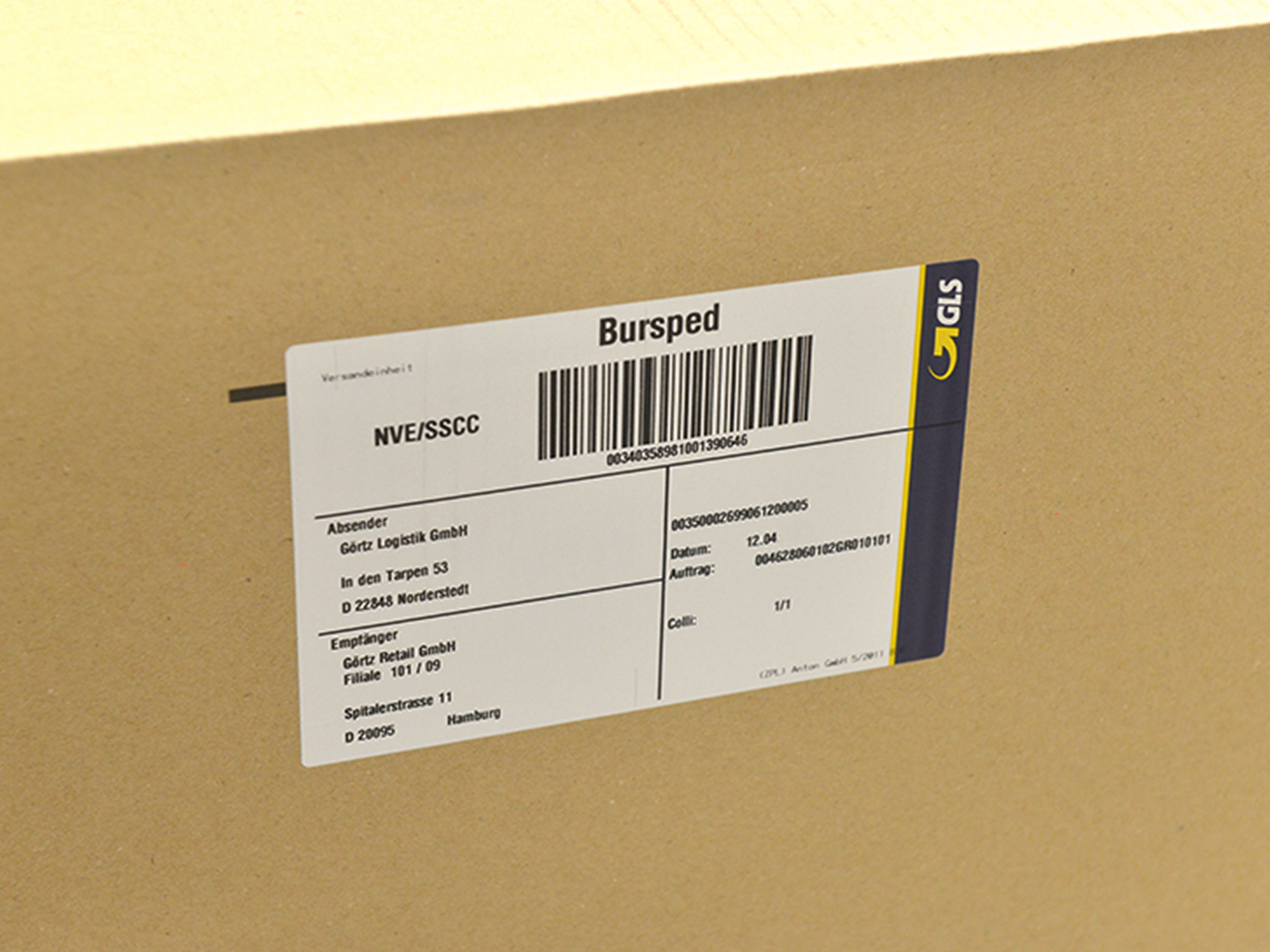

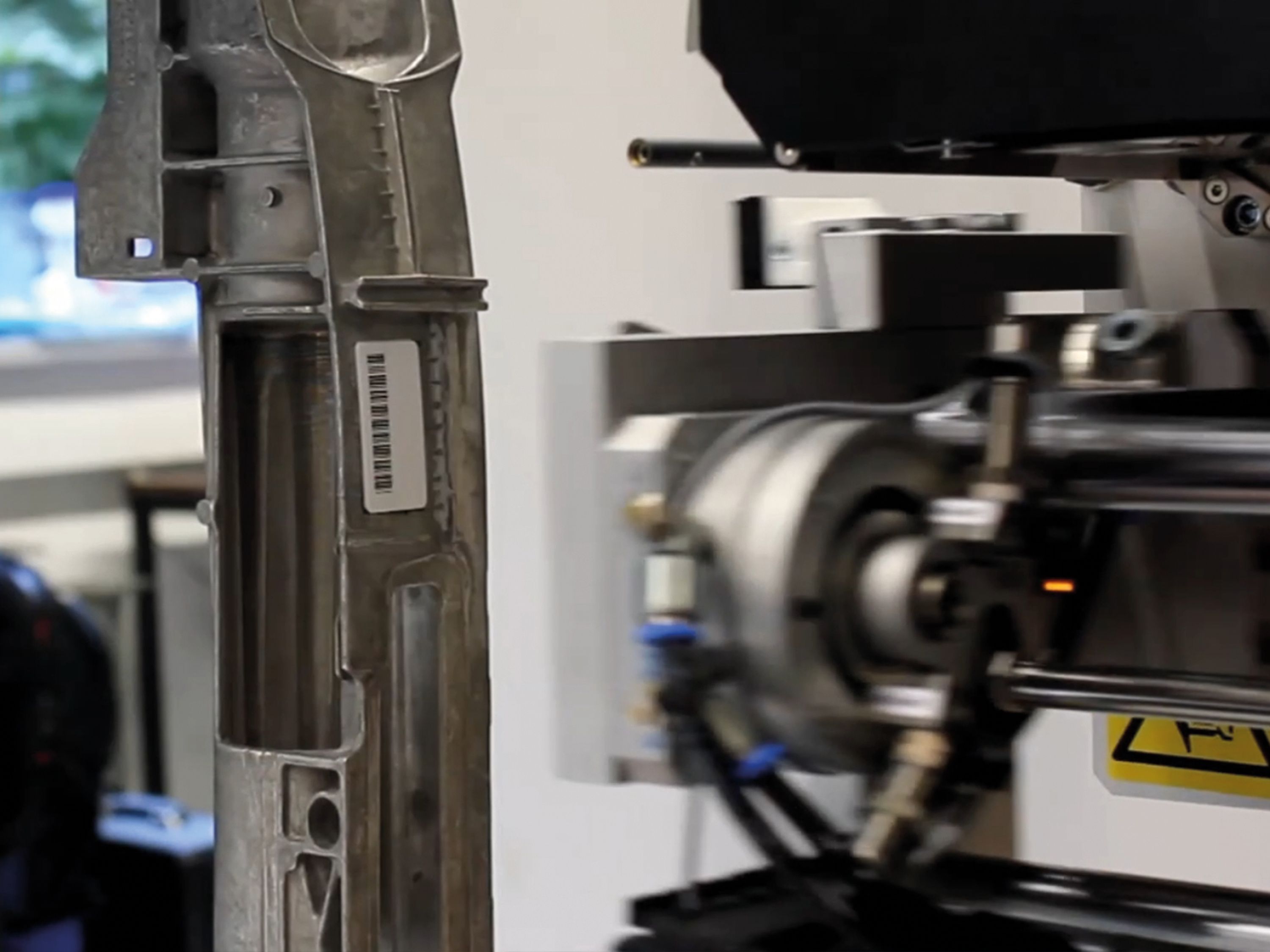

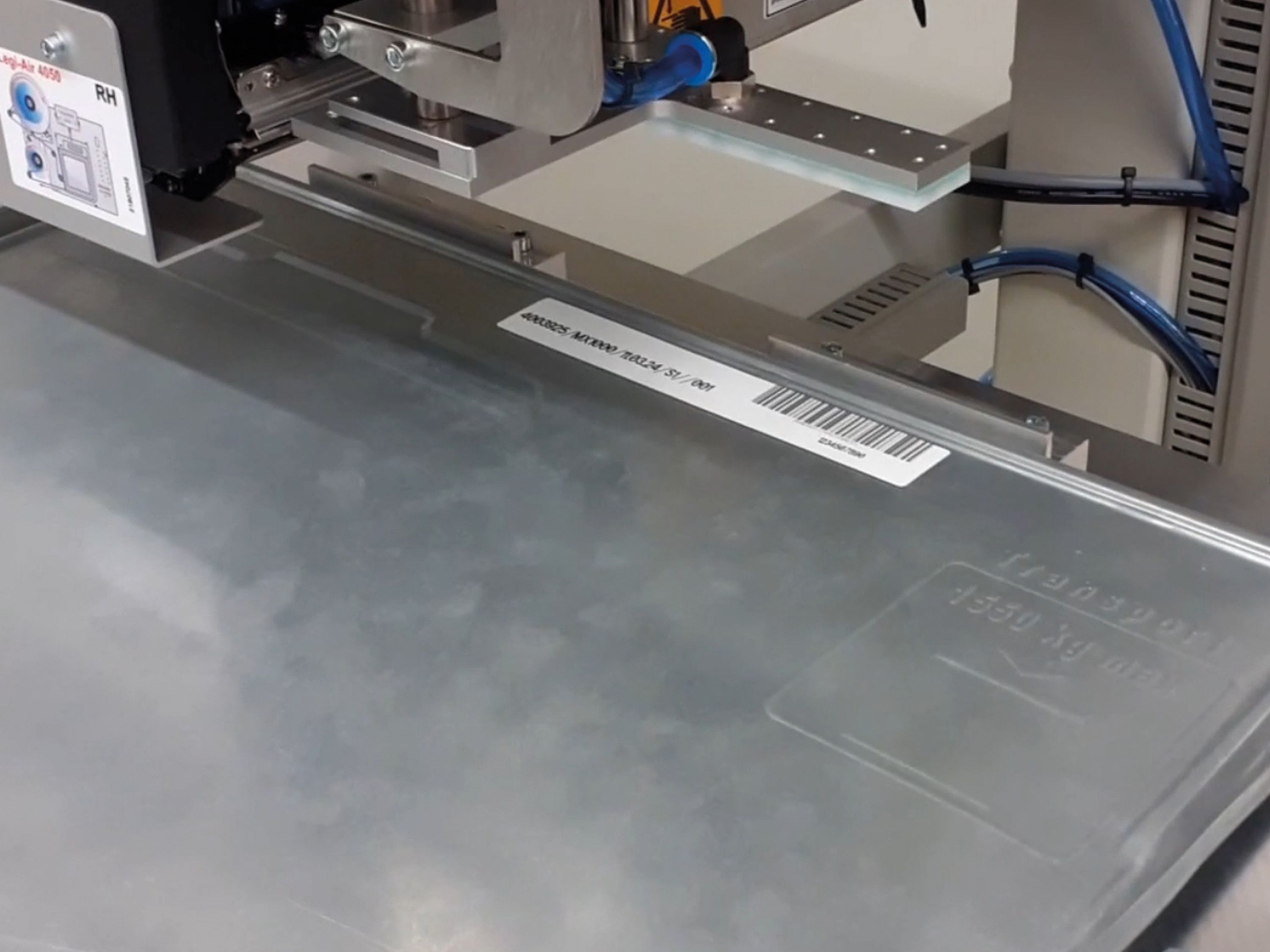

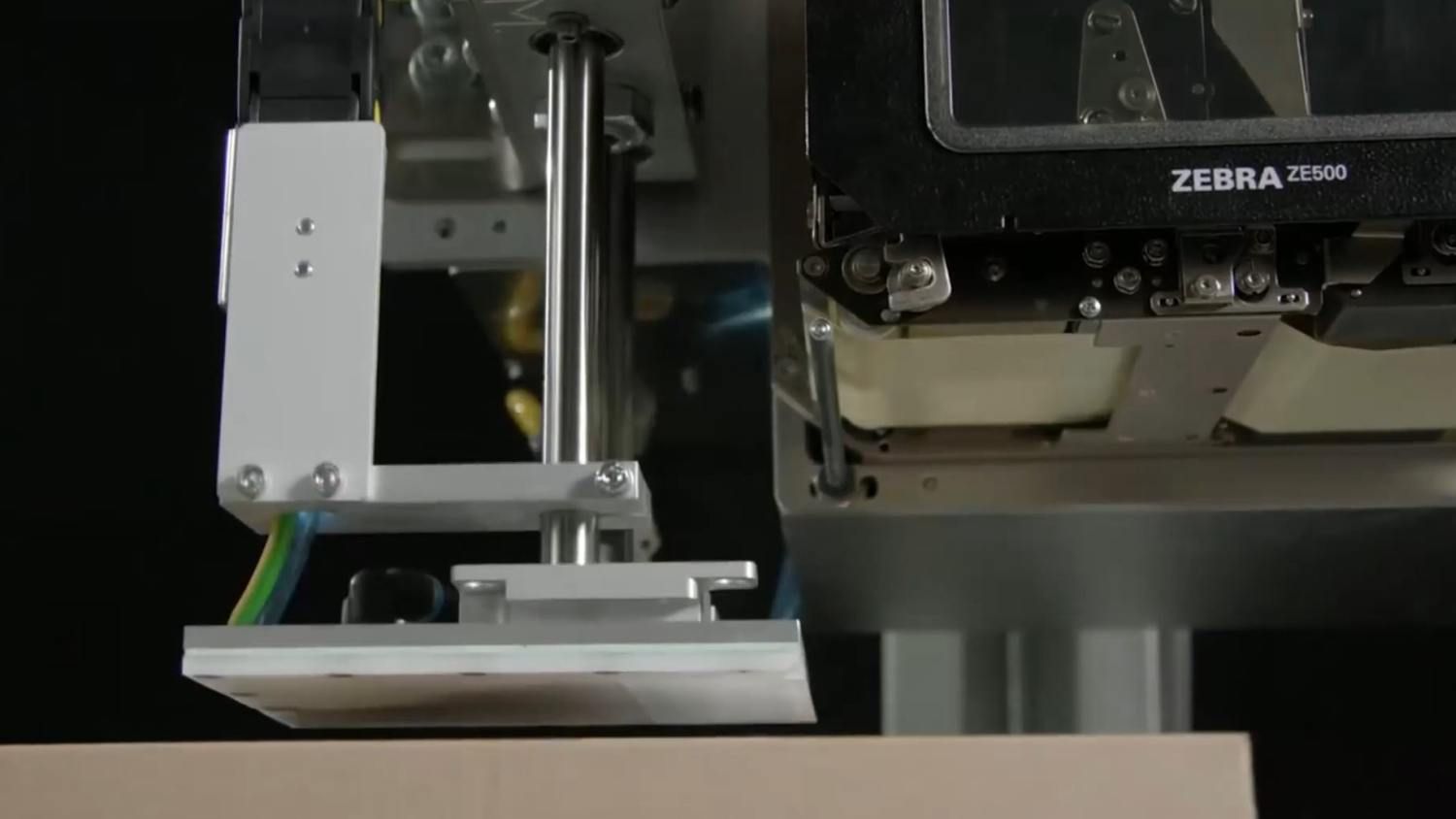

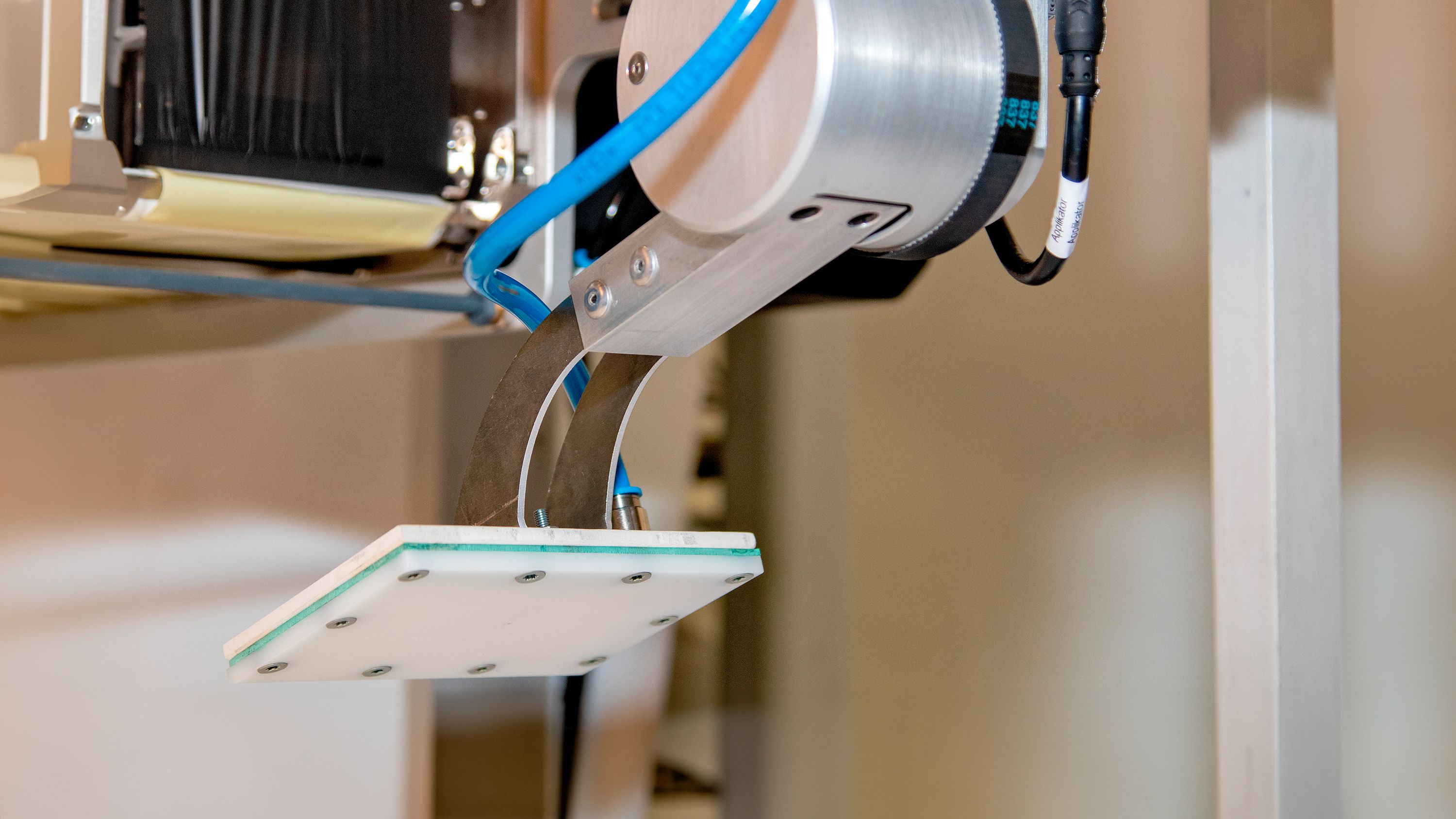

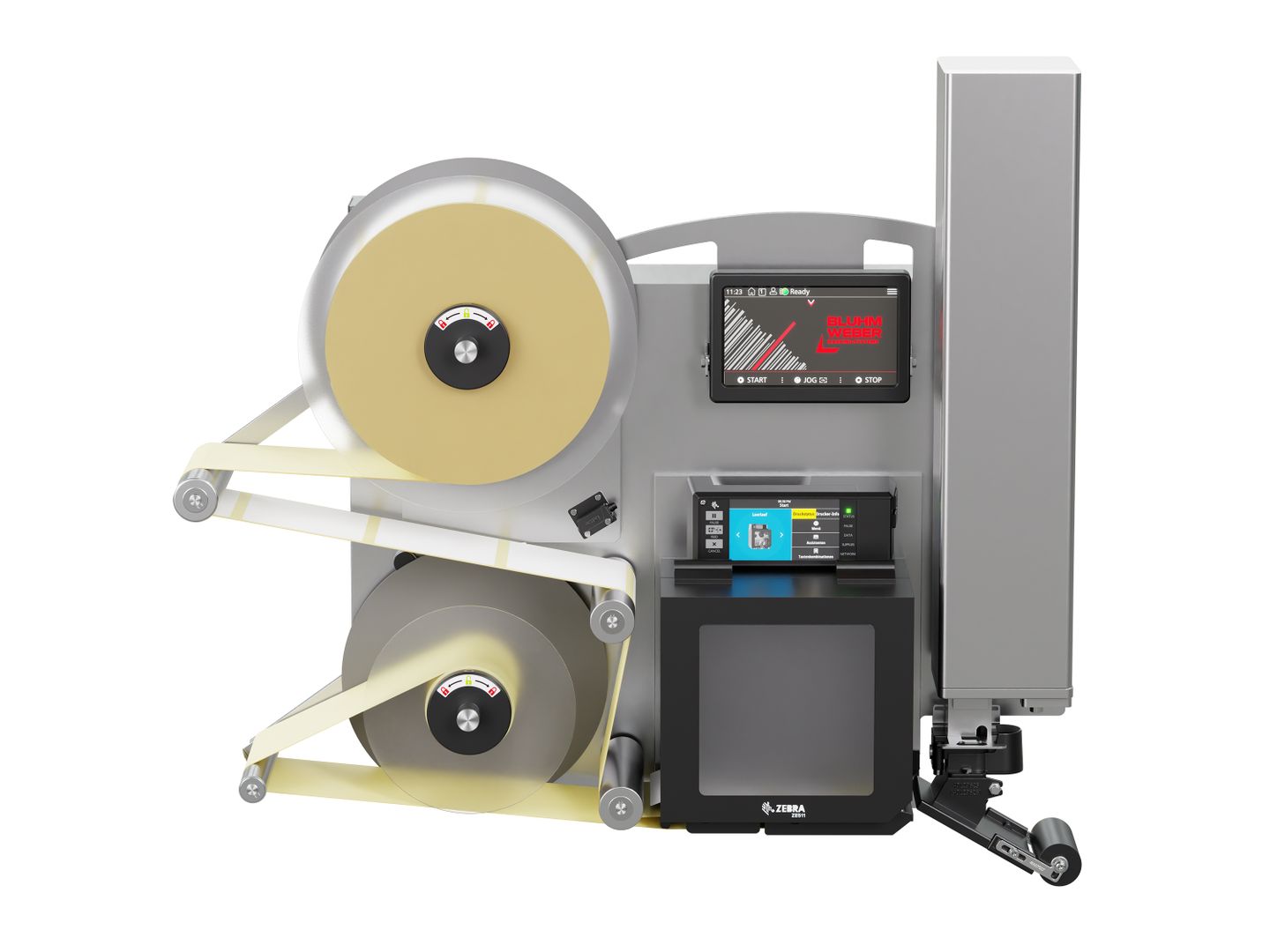

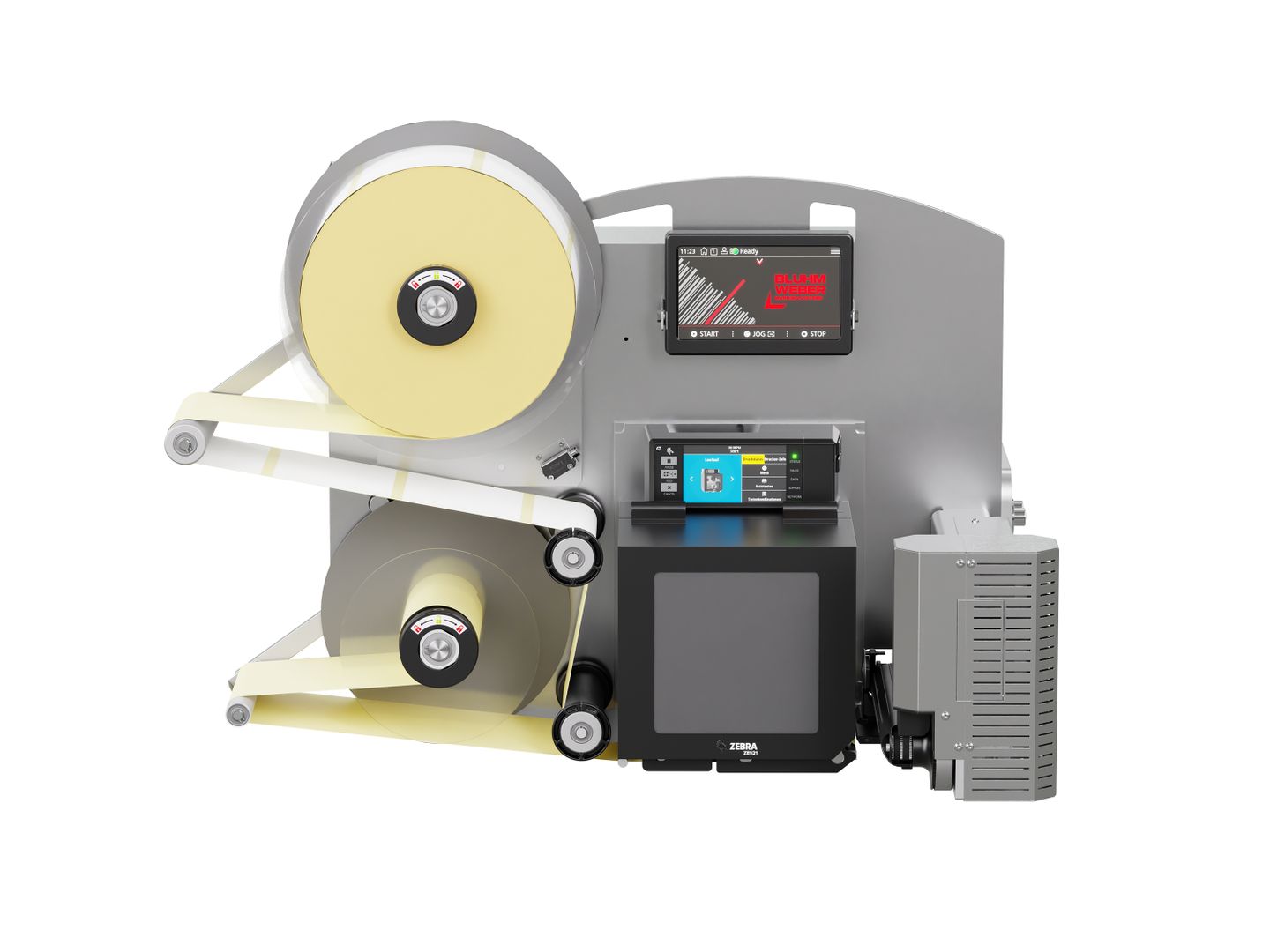

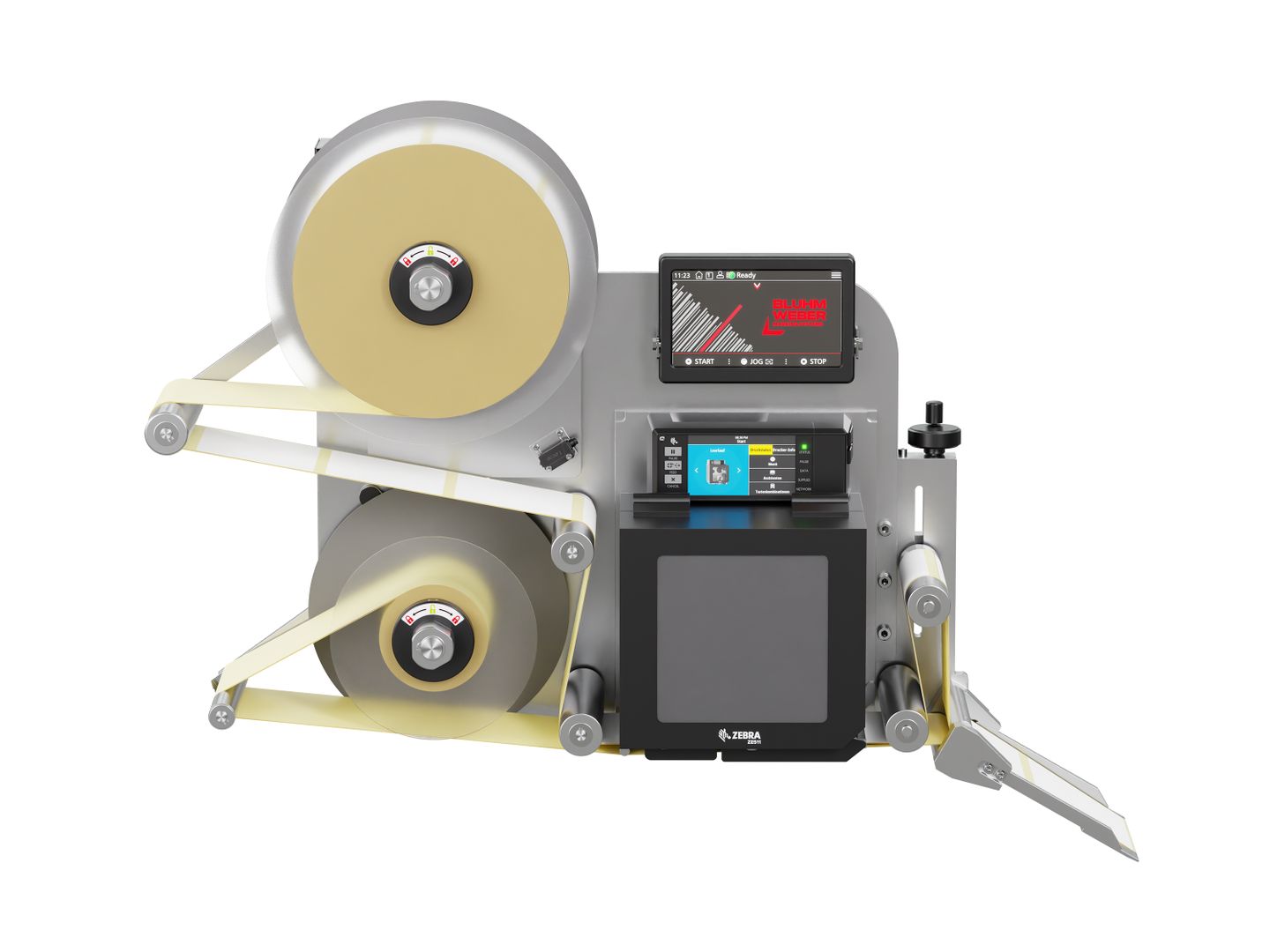

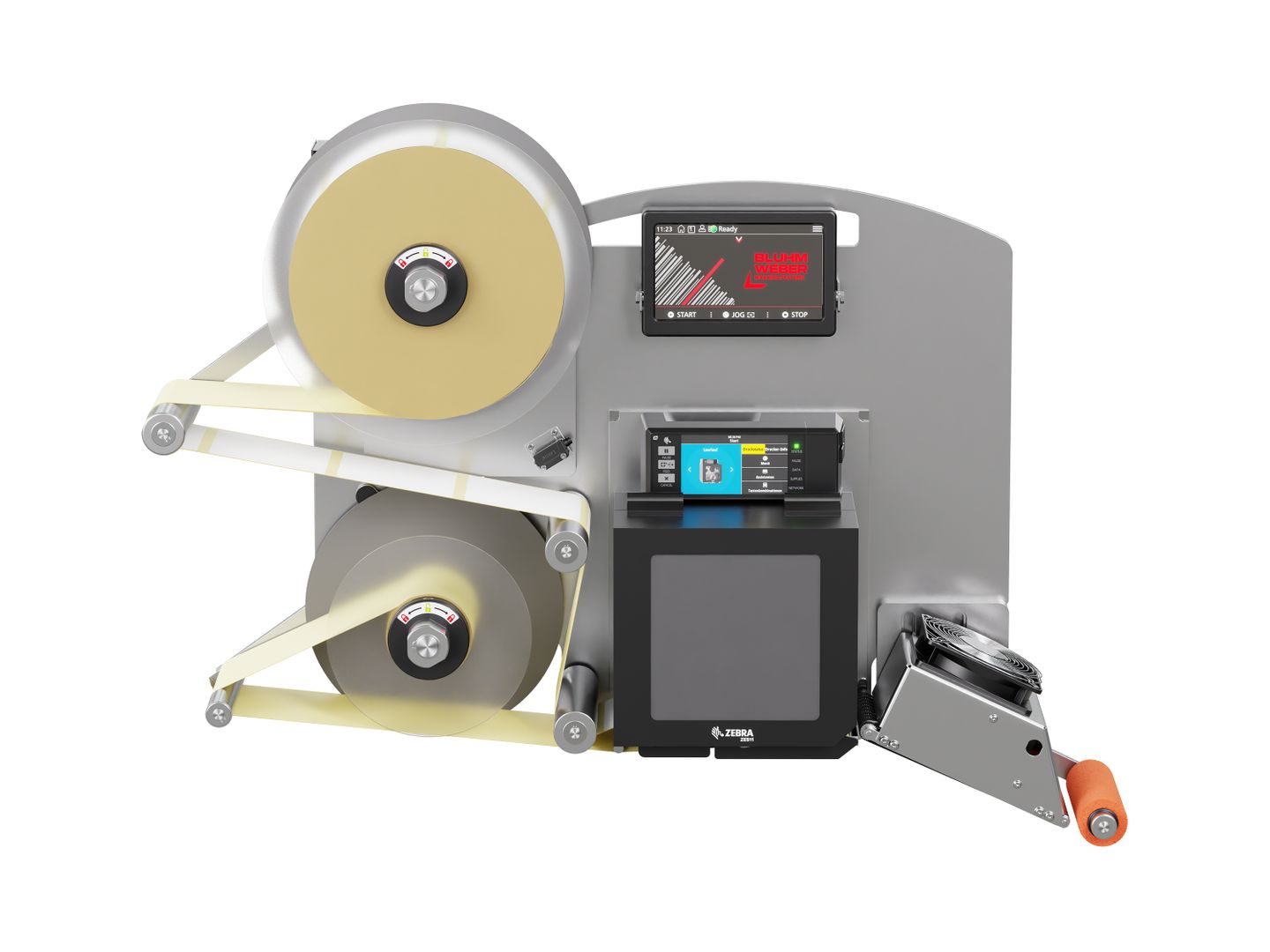

The Legi-Air 4050E is a rugged, compact print-&-apply labeler with a wide range of expansion options. Thanks to a consistently modular design and more than 1,500 applicator variants, the system can be tailored to your specific application. The many available and very robust applicators support any labeling position and speed. Print engines from all leading manufacturers are available for printing the labels.

The print-&-apply system is designed with no scheduled-wear maintenance parts. Components are replaced only as needed. The installed print engine must be serviced in accordance with the respective manufacturer’s specifications.

If required, a bad-tag reject arm is available to automatically eject faulty labels and remove them from the conveyor line. A protective enclosure for integration into production environments with high dust loads, moisture, and/or low temperatures is also available.