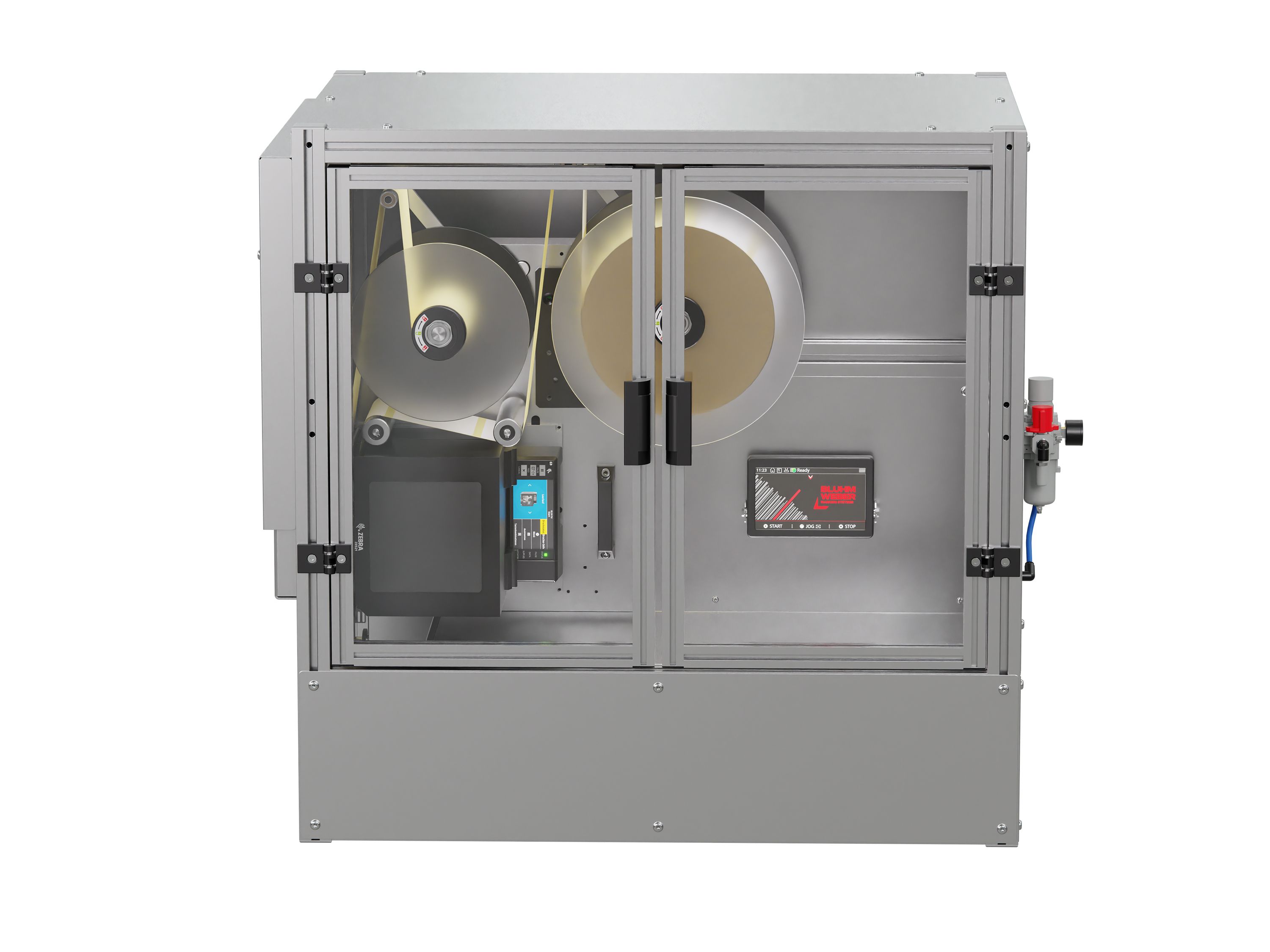

Compact 3-sided labeler with rotating tamp

The AP182RT version of our pallet labeler has a rotating tamp, which enables it to apply labels in various formats upright, diagonally and across onto pallets ready for dispatch. For example, portrait-format transport labels can be processed or landscape-format labels with content information as well as warning notices that are applied at an angle.

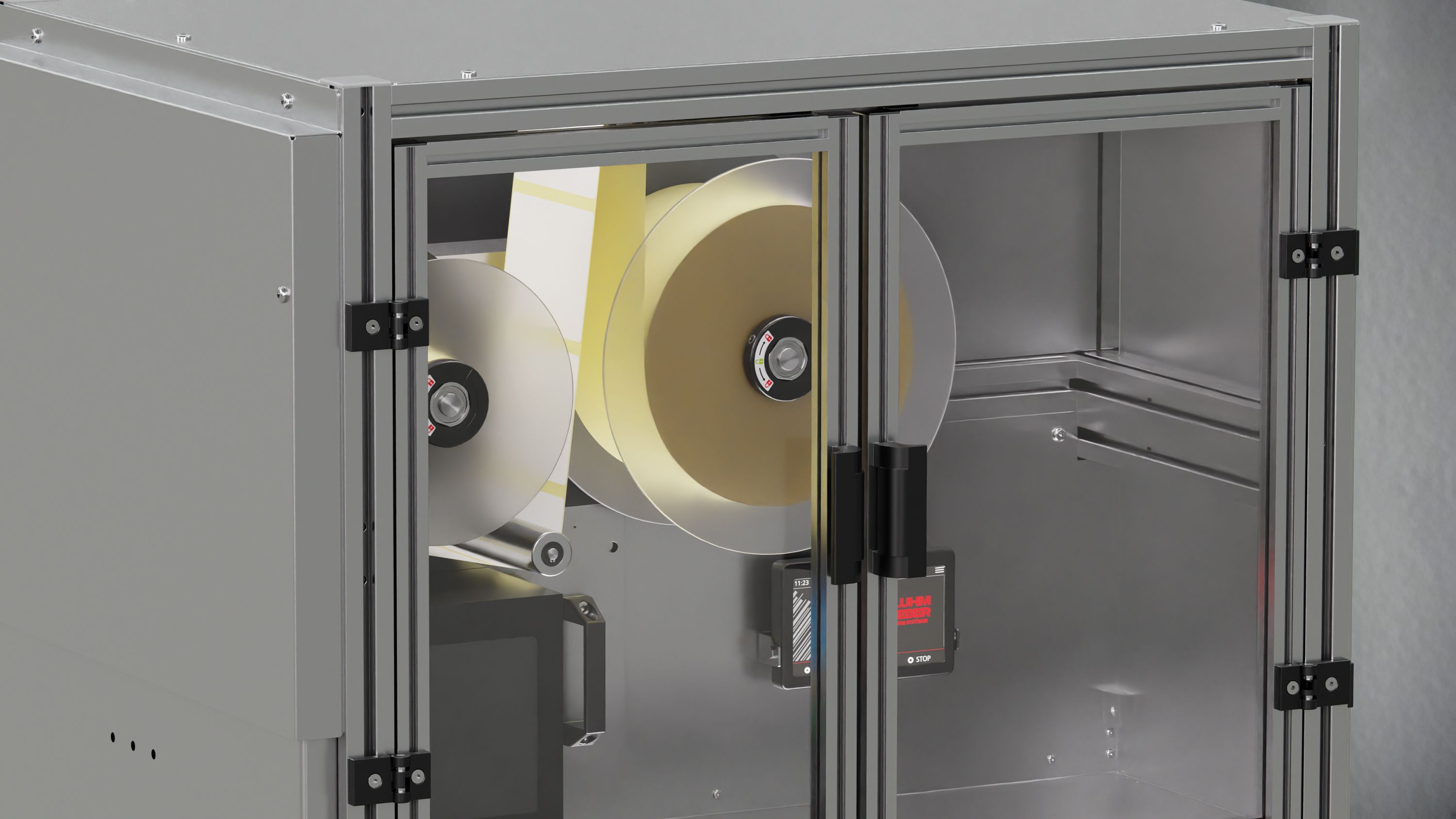

The Legi-Air AP182RT pallet labeler creates and processes GS1-compliant labels in DIN A5 or DIN A6 format; other label sizes are optionally available. The use of label rolls with a diameter of 350 millimetres ensures an efficient and long production time. The AP182RT achieves high speeds of 120 pallets per hour for two-sided labeling and 90 pallets per hour for three-sided labeling.

The labels are printed by an integrated print module. A wide selection of high-quality print modules from renowned manufacturers is available for configuration, achieving print resolutions of up to 600 dpi. As it does not require a safety fence thanks to its intrinsically safe design, the system saves costs and effort in logistics.