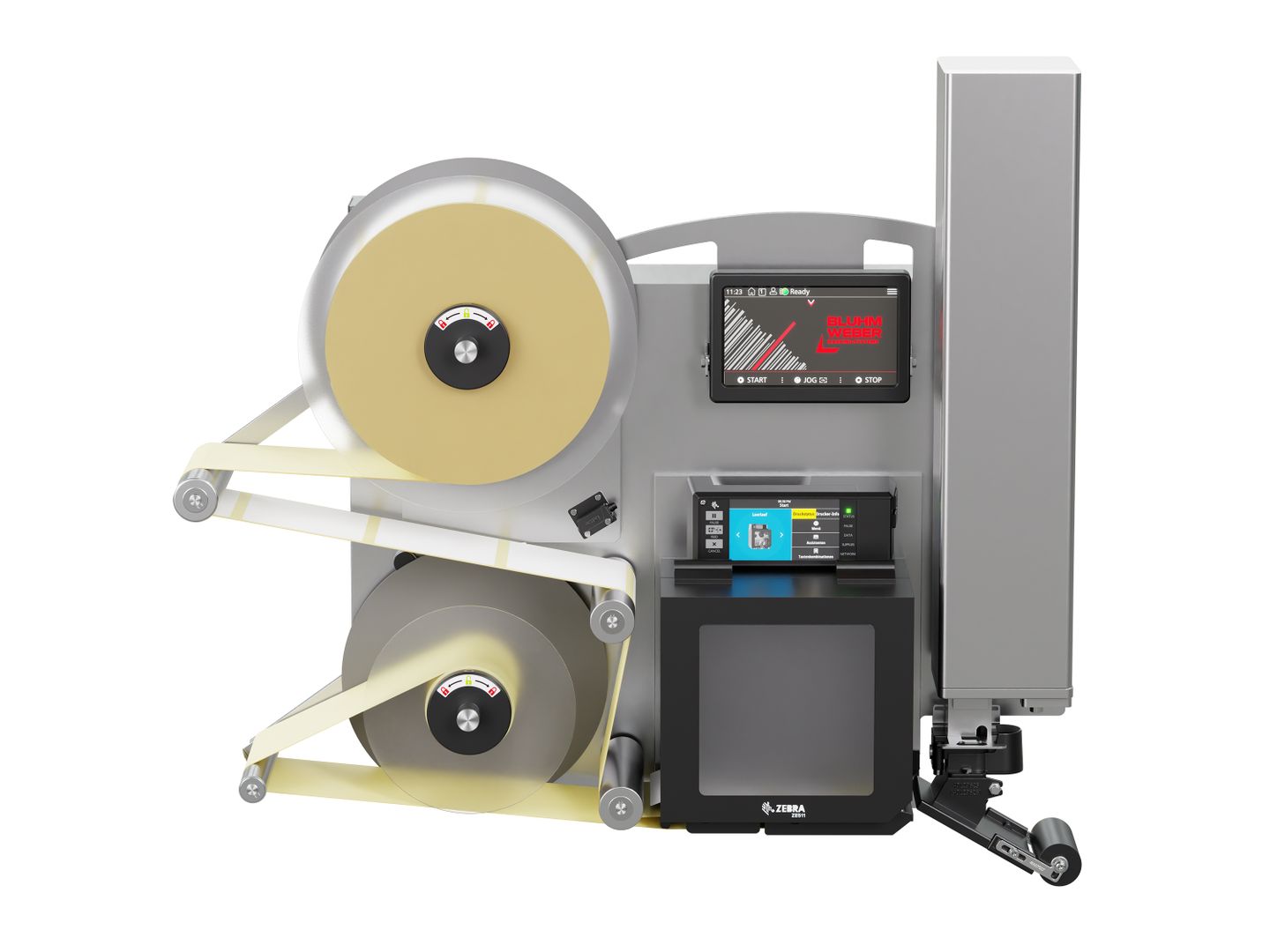

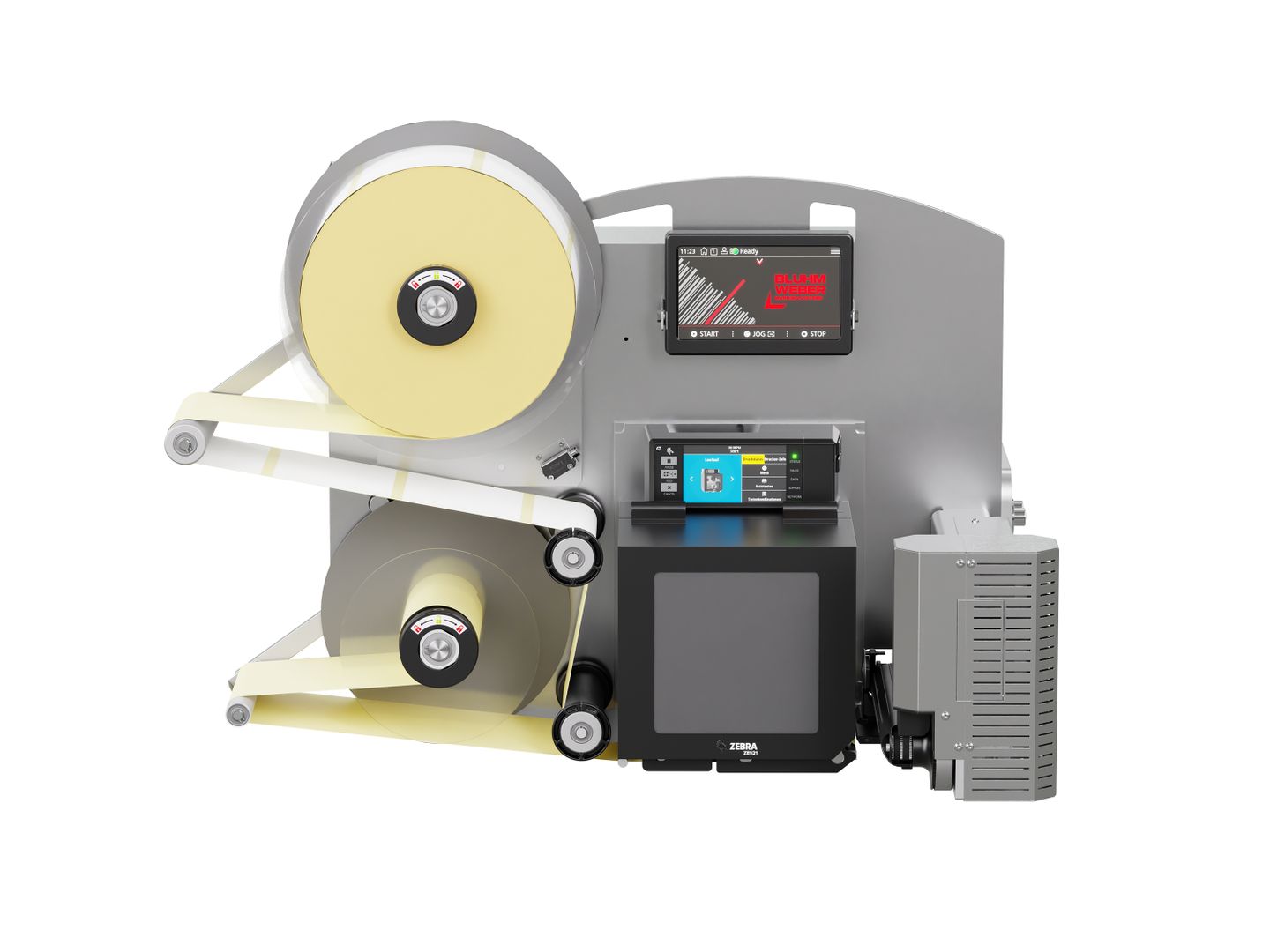

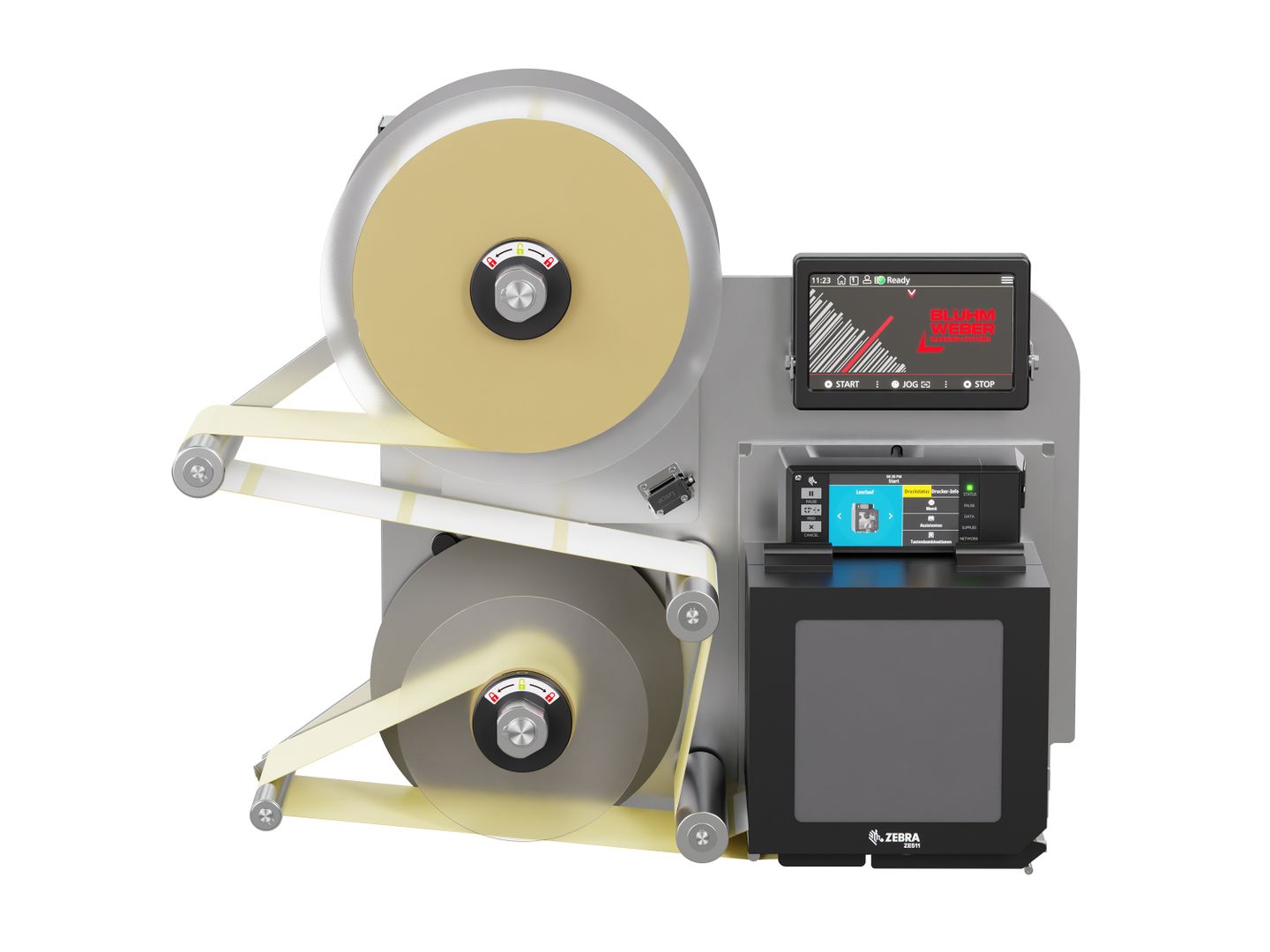

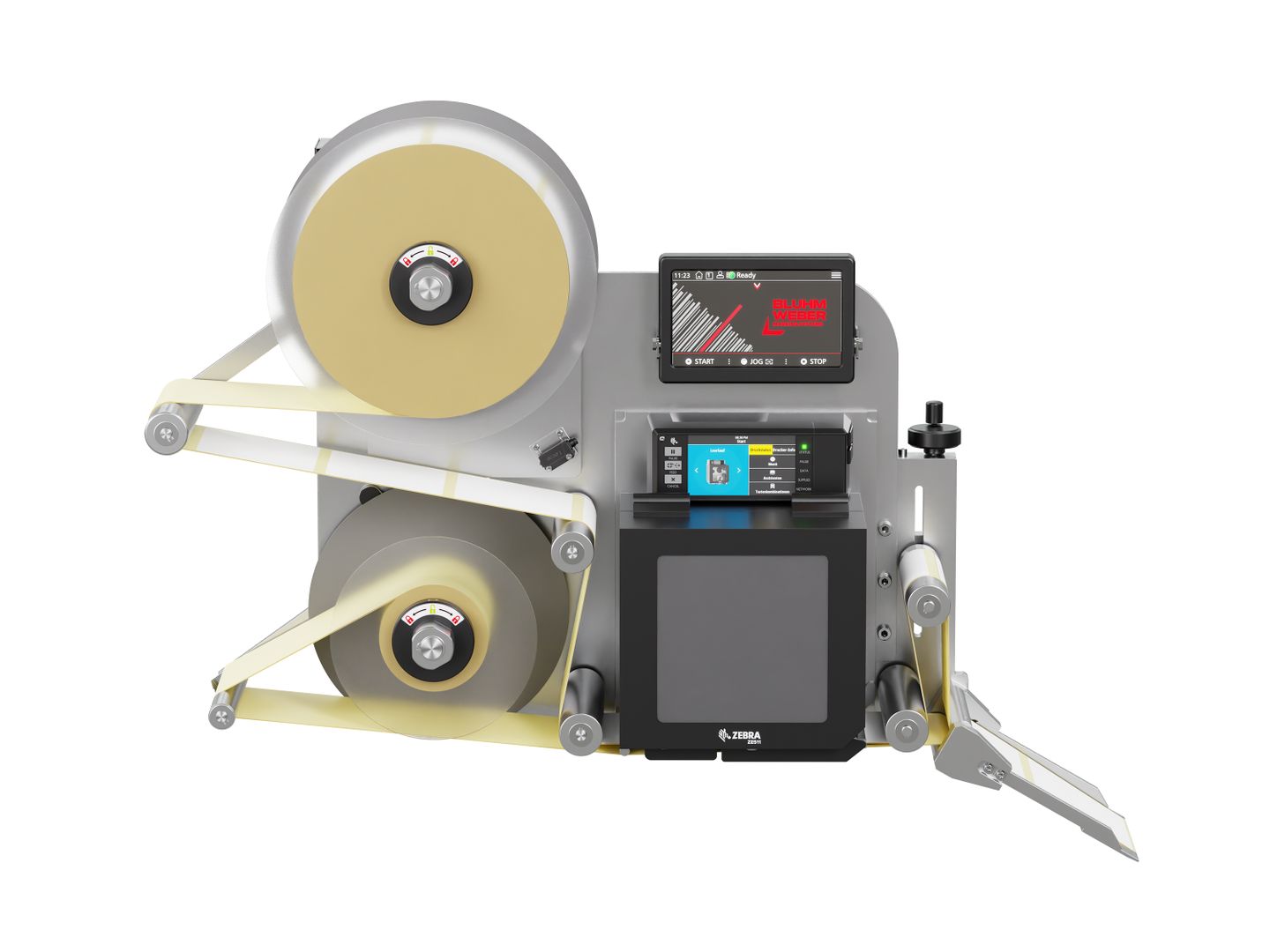

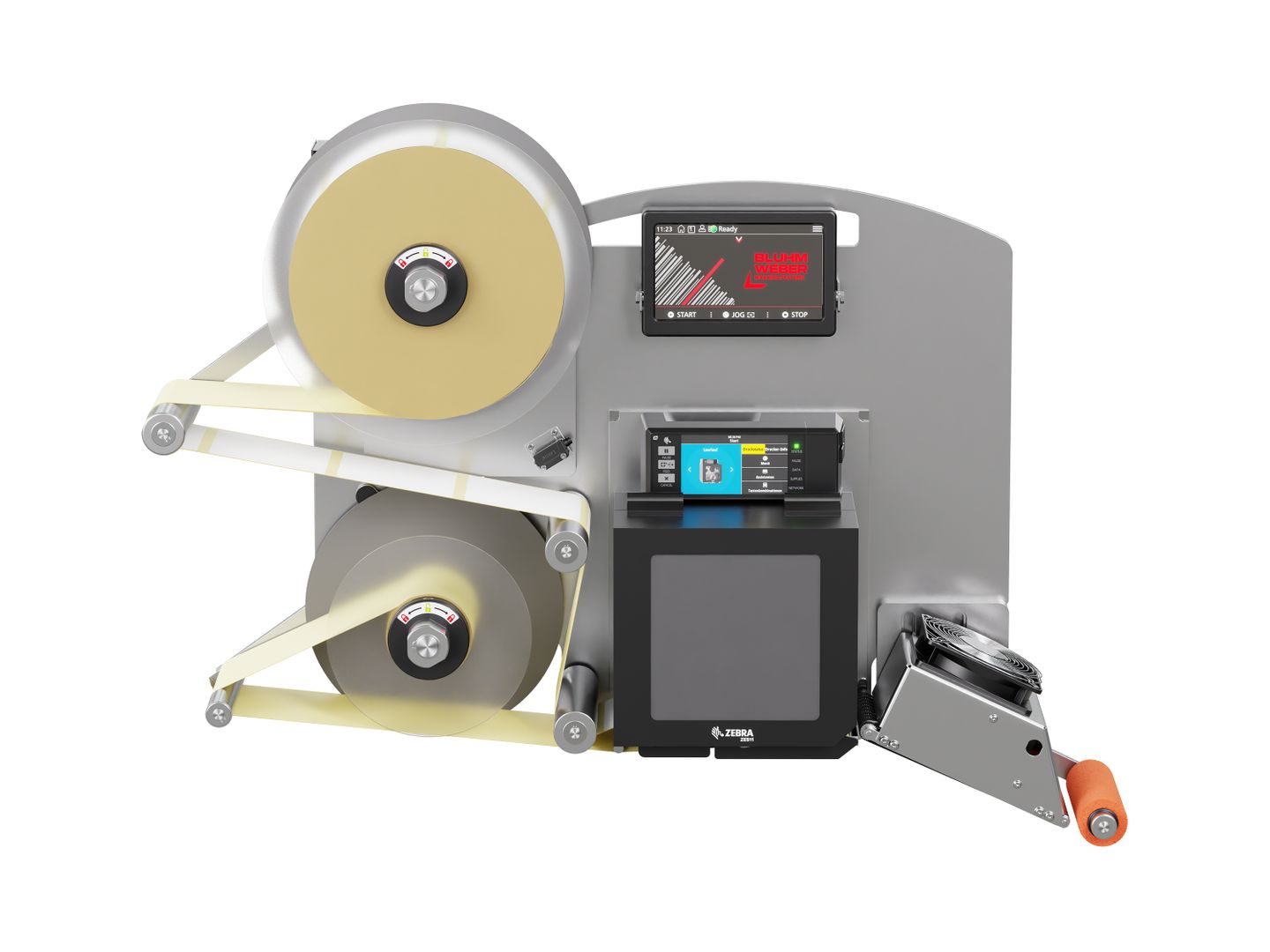

Energy-saving, high-performance label print applicator

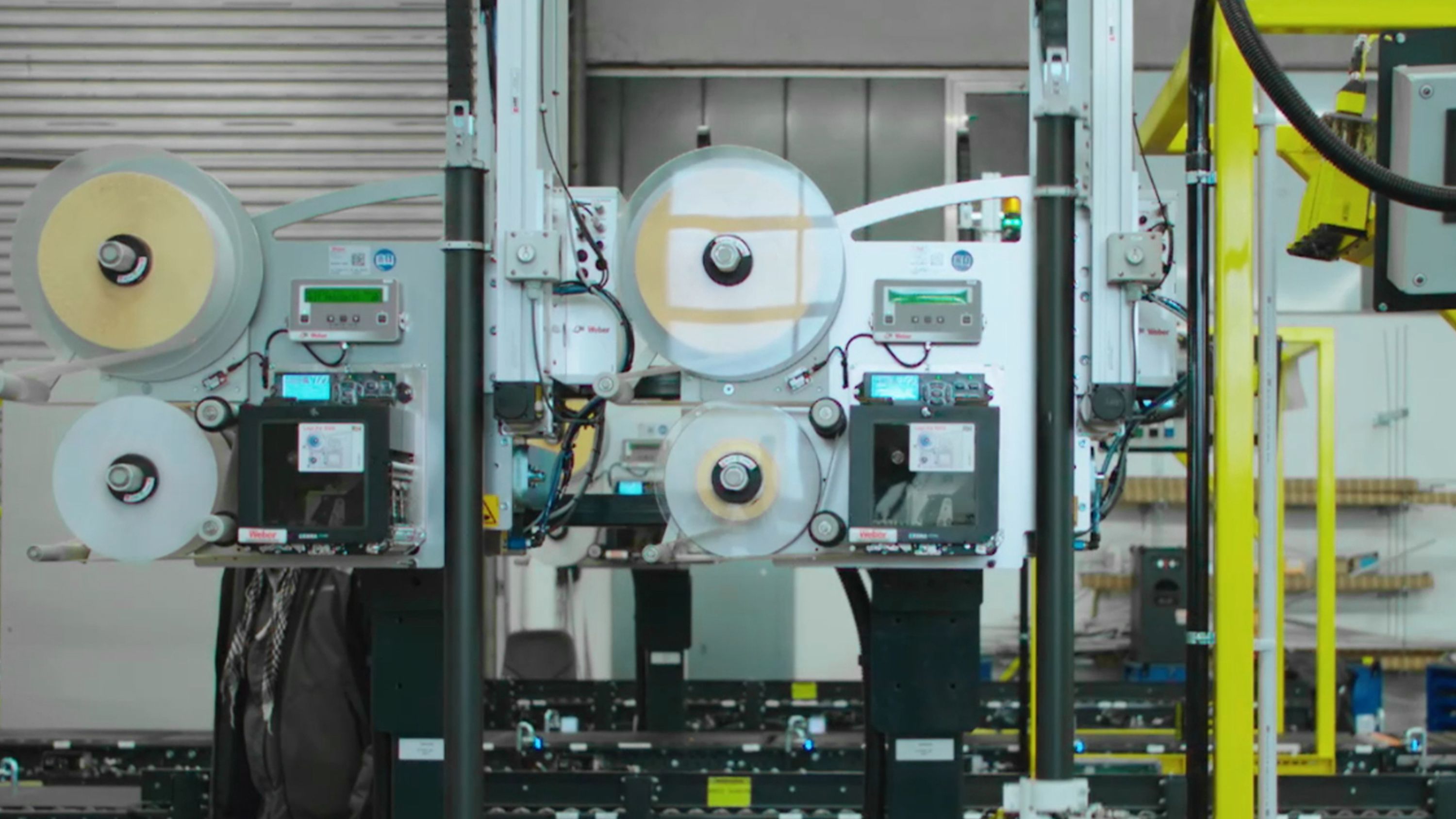

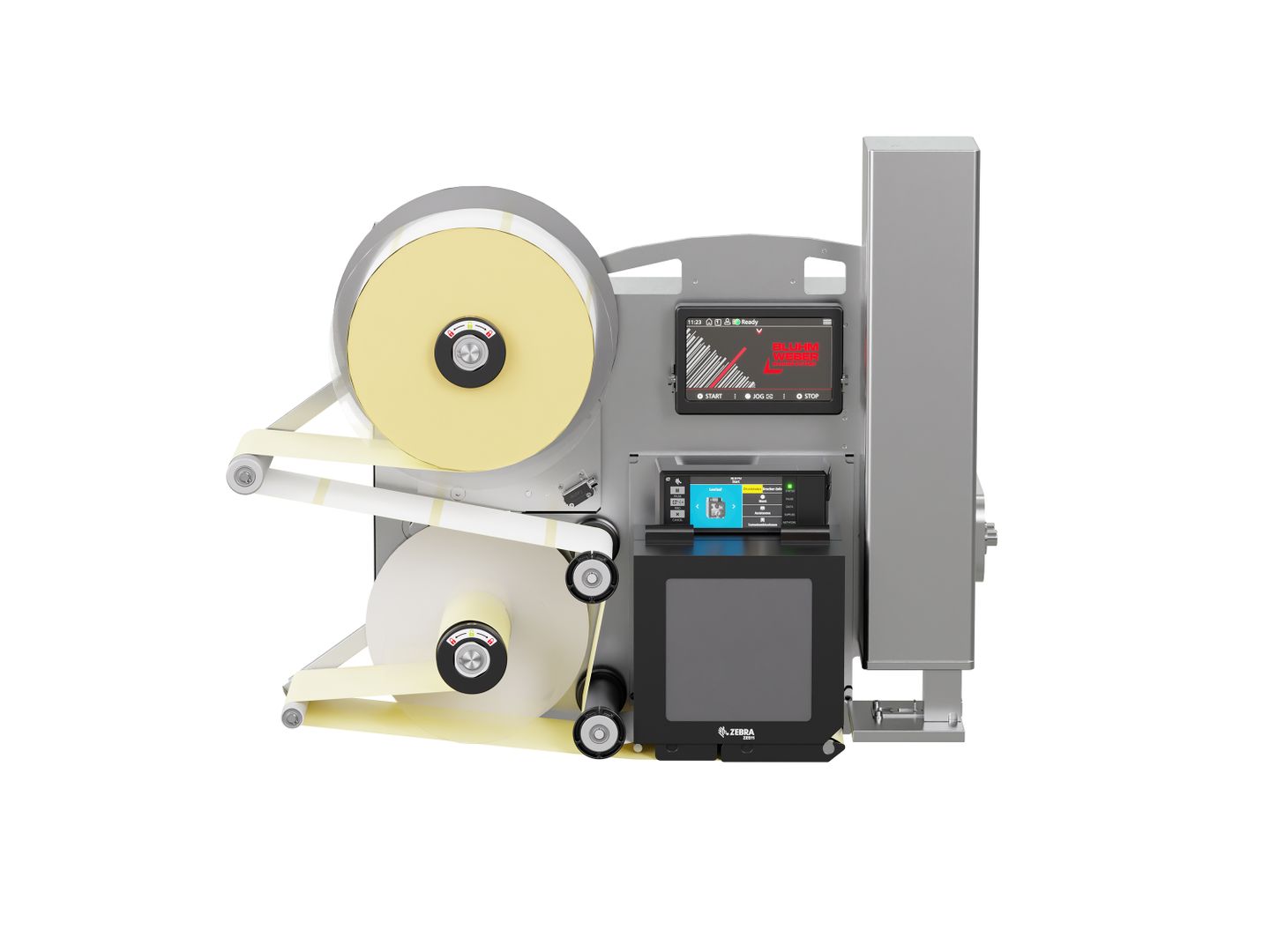

With up to 2,400 products per hour, the Legi-Air 6000 high-speed labeler labels cartons of different heights on the conveyor belt that throughfeeds particularly quickly. Product height differences of up to 500 mm are possible. Once a sensor has determined the height of the product to be labeled, the electric applicator moves into the correct position. As a result, the travel distance during the labeling process is shorter, while at the same time the label print applicator dispenses labels more accurately and up to 50 percent faster than a labeler with a pneumatically operated cylinder. This is supported by the consistent lightweight construction with carbon fibre components for the moving parts. The applicator is around 80 per cent lighter than a conventional model.

Control is optimised in terms of cost and space by a microprocessor controller. There is no need for a separate control cabinet, so the compact device can be easily integrated into production environments. The modular design allows a high degree of customisation and easy integration into existing production lines.