Reliable pallet labeling around the clock

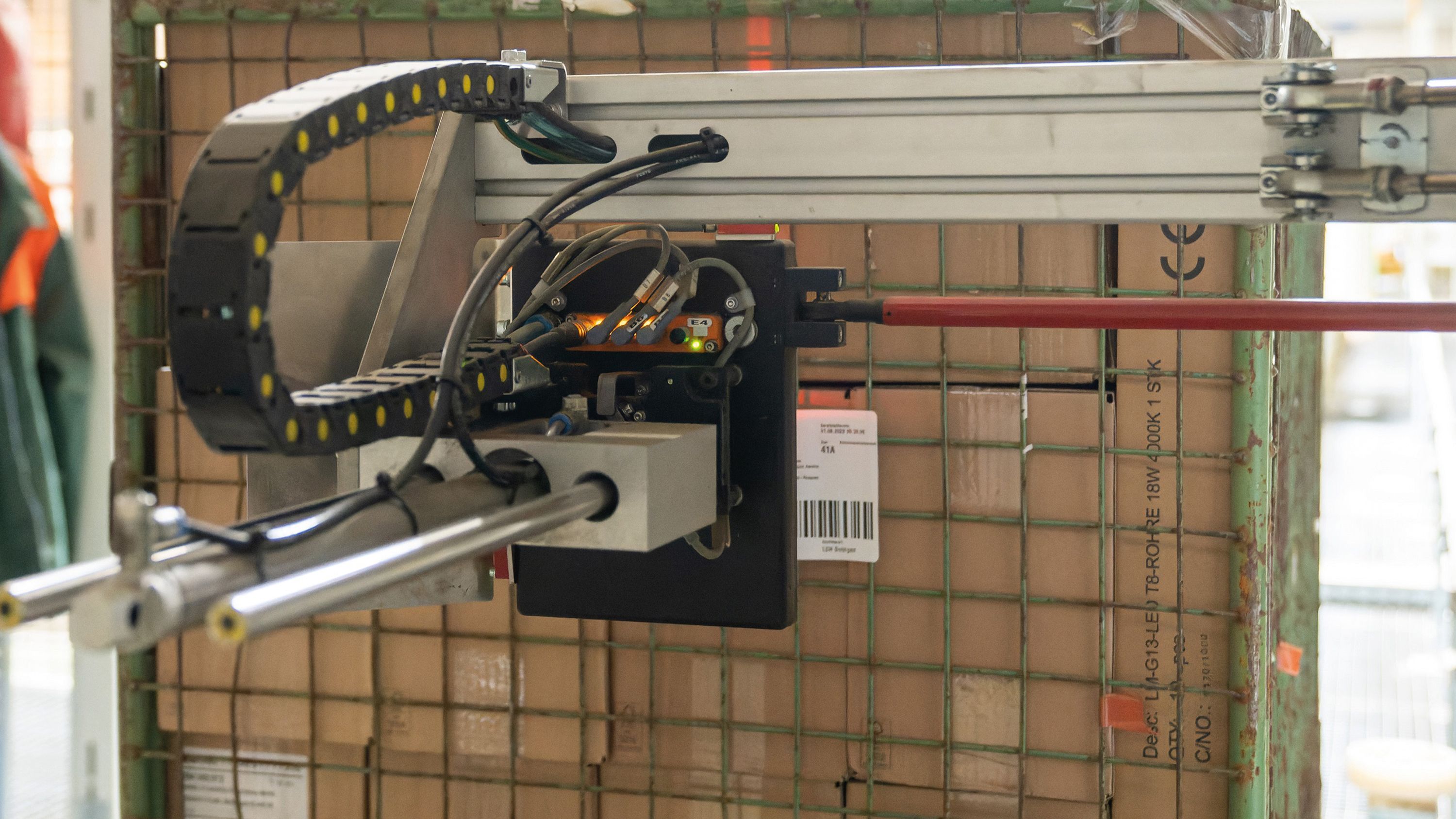

The Legi-Air 4050E(L)2A is the ideal solution for automated pallet labeling in continuous industrial operation. Thanks to its powerful applicator technology – available in a short (E2A) or long (EL2A) version – the system enables precise single- or dual-sided labeling of pallets, both in motion and at standstill.

With up to 420 labeled pallets per hour, the 4050E(L)2A is one of the fastest pallet labeling systems in its class. Two independently operating pneumatic circuits ensure reliable label fixation even in the event of a supply interruption. A user-friendly 7-inch touch display, electric rewinders and unwinders, as well as various options such as protective housing or Performance Level D, complete the system. The Legi-Air 4050E(L)2A – engineered for maximum efficiency, reliability, and ease of use.

2A_applicator.jpg)

2A_stamp_with_sensor.jpg)

2A_electric_winder.jpg)

2A_protective_housing.jpg)